Oct 31 2025

/

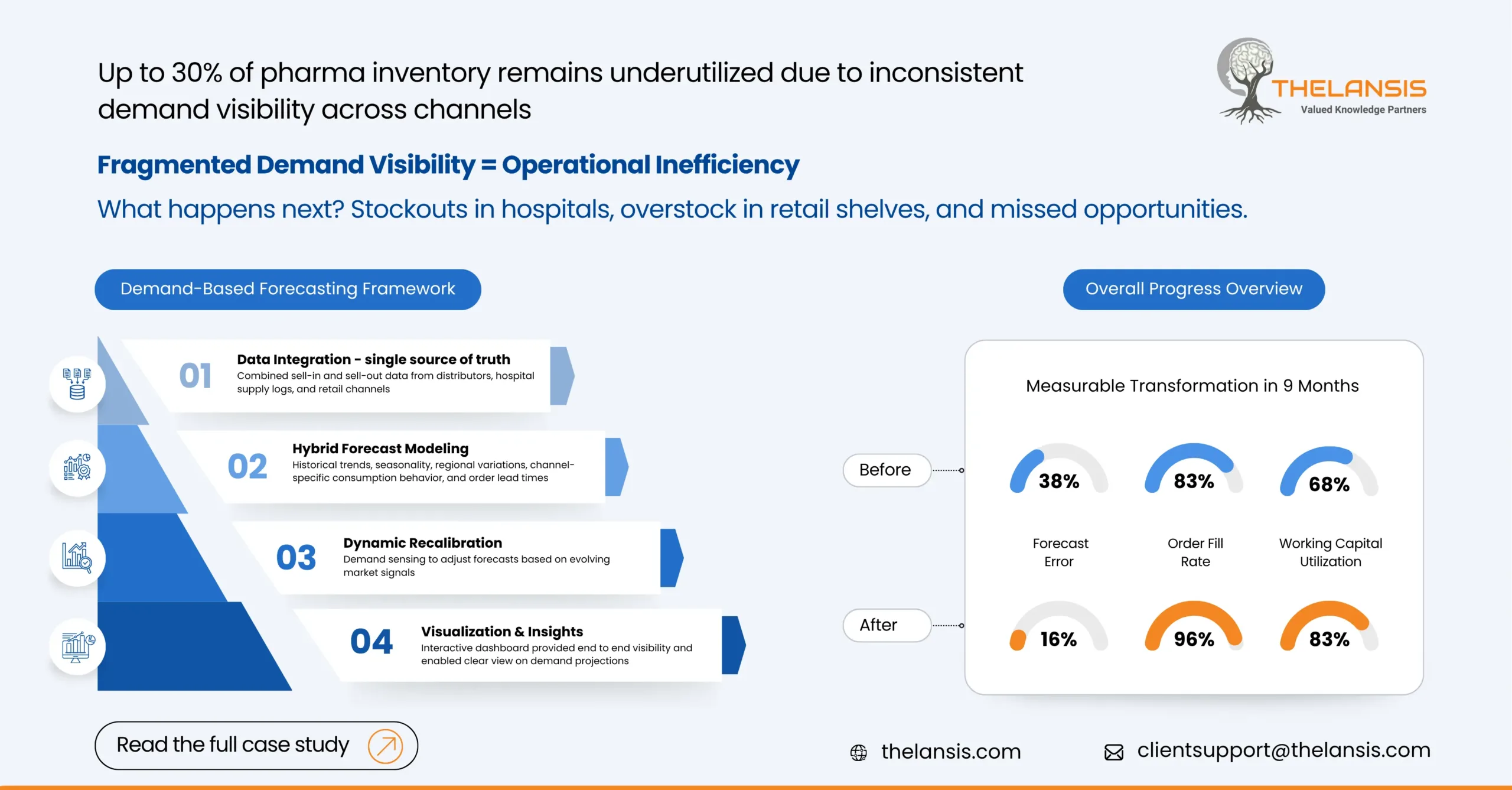

Optimizing Multi-channel Distribution and Inventory Agility in Pharmaceutical Industry through Demand-Based Forecasting

Introduction:

The pharma ecosystem is quite complex, wherein companies operate across various channels, ranging from hospital procurement networks to retail pharmacies. While this expands their market reach, it also creates challenges in forecasting demand because of fragmented data sources, channel silos, and inconsistent demand visibility. This results in inaccurate forecasts, which leads to stockouts, overproduction, and wasted resources.

However, using demand-based forecasting can help organizations match their production and distribution with real market consumption, ensuring consistent product availability, minimizing wastage, and bringing operational excellence.

Problem Statement:

One of our clients, a mid-sized pharma company, reached Thelansis with a key challenge: despite their robust sales across hospital and retail channels, they were facing persistent forecasting inconsistencies resulting in stock imbalances, overproduction in retail channels, and understocking in hospitals, which led to service level gaps and inefficient inventory holding.

Our team gauged the absence of a unified demand forecasting framework, causing limited data transparency across distributors and hospitals.

Objective:

Our goal was to implement a robust demand-based forecasting framework that could consolidate data from multiple channels and deliver accurate, actionable forecasts to guide production and inventory planning.

Solution Framework:

Thelansis deployed a structured, analytics-led framework integrating technology, data science, and domain expertise:

- Data Integration: Combined sell-in and sell-out data from distributors, hospital supply logs, and retail channels into a single data lake, ensuring a single source of truth.

- Demand Forecasting: Developed a hybrid demand model that incorporated historical trends, seasonality, regional variations, channel-specific consumption behavior, and order lead times to predict demand across channels.

- Dynamic Recalibrations: Applied demand sensing algorithms to adjust forecasts based on evolving market signals, including hospital tender outcomes, promotions, regional demand surges and recent sales performance.

- Visualization & Insights: Implemented an interactive dashboard that offered end-to-end visibility and enabled stakeholders a clear view of short-term and long-term demand projections for better planning alignment across production, procurement, and logistics.

Result:

The solution generated significant business impact within 9 months of organizational-level integration:

- Reduced multi-level forecast errors, such as franchise, distribution network, and country level by 22%, leading to improved planning confidence

- Achieved order fill rate of 96%, accounting for higher SLAs

- 15% improvement in working capital utilization through optimized inventory planning and deployment at various levels of the organization.

With demand-based forecasting, the client shifted to a data-driven supply chain that improved market alignment, cut costs, and increased customer satisfaction.